A Cool Super Graphic Article

© By James S. Vilett

![]() start

start

The parent company of Graflex started in 1887 as Folmer and Schwing Manufacturing Company of New York. Folmer Graflex Corporation operated from 1928-1946. Between 1946 and 1955 the Company became Graflex Inc. It became a division of General Precision Equipment, Rochester New York from 1956 until 1968. From 1968-1973 it was a division of Singer Corporation (still following the thread). The company closed in 1973 (after 83 years), which was the pits. The Graflex plant is located at 3750 Monroe Avenue in Pittsford, New York and is still standing. The Sakai Tokushu Camera Company Ltd Japan bought the dies for the Super Graphic and continued to make the Toyo Super Graphic 4x5 camera until 1985. This last fact alone would suggest that the camera was a pretty great camera. Or, it might indicate that Sakai Takushu Camera CO. of Japan was out to make a fast buck. Your choice.

Super Graphic body shell

Earlier Graphic 4x5 press cameras were hand crafted wooden bodies. (You may just see the neat dovetail joints on the top side edge of the wooden Graphic body pictured here). The Super Graphic was a fully new camera design made of reinforced extruded aluminum. It was designed for maximum strength with minimum weight; (also my own personal goal) the complete camera was only 4½ pounds. The Super Graphic camera was available from 1958 until 1973. A different version of the camera; the Super Speed Graphic was available from 1961-1970. Both basic camera bodies were the same.

![]()

Graflex 1000 shutter

Graflex 1000 shutter

The Super Speed Graphic came with a 135mm f4.5 Graflex Rodenstock Optar lens in Graflex 1000 shutter. This is probably the only view camera shutter that had a top action-stopping speed of 1/1000th of a second. Cocking the shutter is fun... you turn the thick ribbed lens shade clockwise fully one-third turn. The shade screws off counter clockwise which allows Series Six drop-in filters to be used. There is a lens open/close lever on the lower left and an M/X sync lever on the lower right. This is a great shutter when it works but requires a real expert to work on. It is very complex inside with huge numbers of ultra tiny parts. That is not to say that most other types of view camera shutters are not also complex; but this shutter is much harder to work on than other types of shutters. A German made Compur shutter is easy to work on when compared to this Graflex shutter. Certainly there are no new parts available for shutter repair. The camera had many special and innovative features for its day. As an easy to operate user friendly and affordable hand camera this is one of the best choices for large format photography. The Super Speed Graphic had an original list price of $680.30 but was available mail order for around $549. Today a very clean fully functional example might be hard to come by, and could easily be worth $850-$950. That assumes one wishes to take high quality pictures on actual 4x5 film.

The Super Speed Graphic had an all metal body. An automatic flash computer was built into the top. The shutter could be released manually or with an electric solenoid body release. There was a rangefinder which allowed for custom cams for each different lens. The rear focal plane shutter was no longer available in this model which made for a lighter camera. The front standard was much improved over earlier models. As stated earlier, a special lens shutter allowed for a top shutter speed of 1/1000th of a second.

90mm Super cam

Super Graphic Rangefinder

Super Graphic Rangefinder

A built in rangefinder used specially ground metal cams. It allowed lenses from 90mm to 380mm to be coupled to the top rangefinder. The rangefinder was built inside the top of the metal body shell. This made for a much more streamlined appearance when compared to earlier Crown Graphic Top Rangefinder 4x5 cameras. Cams were a 1mm thick flat piece of metal cut in a curve along one side (to match each lens), and were inserted inside the top of the camera. This allowed the camera rangefinder to be matched to whatever focal length of lens you were using. Even lenses which were made by exactly the same manufacturer, and were exactly same focal length needed different cams. Every lens has slightly different focusing points; which depending on how it was originally ground at the factory ,and the manufacturers original optical design. The Graflex service department offered a service to measure the exact focal length of your lens. Rangefinder cams could be specially cut by the Graflex service department to match whatever lens you desired. You are going to have trouble getting them to grind your cam now. If you've got a cam to grind be sure to do it somewhere else. One weak part of the top rangefinder is it was coupled to the bottom focusing bed with a metal tube filled with about 100 very tiny ball bearings. This should have a major bearing on your choice not to work on this part of the camera. My suggestion is it is better not to take this portion of the rangefinder apart unless you know what you are doing. The rangefinder is a weak part of the camera as it will stick if any of the parts kink and no longer line up correctly. A flat metal tape connects the focusing bed to the range finder coupling tube. If the tape developes a bend when the camera door is folded closed for to many years then the rangefinder binds. When buying a camera look for kinks in this metal tape. It is best not to buy a kinky rangefinder.

Revolving Back

Revolving Back

A revolving Graflok back was standard. (Graflok just meant the focusing panel came off using spring locks to allow 120 roll film backs to be used. Many earlier Graphic cameras had spring style backs which did not come apart and were suitable only for sheet film.) The spring locks on the top and bottom right side of the Super Graphic back may be pressed to remove the back. The back could revolve fully 360 degrees in either direction even while film was loaded in the camera. It allowed the photographer to take horizontal or vertical pictures with the camera mounted on a tripod. Film holders could be inserted from the side or the top. The end of the plastic release lever (see upper left in picture below) that unlocks and allows the back to revolve is sometimes busted off on well used cameras.

The entire focusing panel was removable to allow mounting of 120 roll film holders. Two slide locks secured the holder to the camera back. Graflex Roll film holders for 4x5 cameras came in three formats 6x6cm (RH12); 6x7cm (RH10); and 6x9cm (RH8). These holders took 12, 10, or 8 exposures per roll of 120 and were named accordingly (RH8, RH10, RH12). In addition a RH20 took twenty 6x7cm format pictures on 220 film. A removable clip-on four sided viewing hood snapped on above the ground glass. The 4x5 ground glass had and Ektalite plastic screen installed behind the glass. This made for much brighter images; and thus easier viewing with much better quicker focusing.

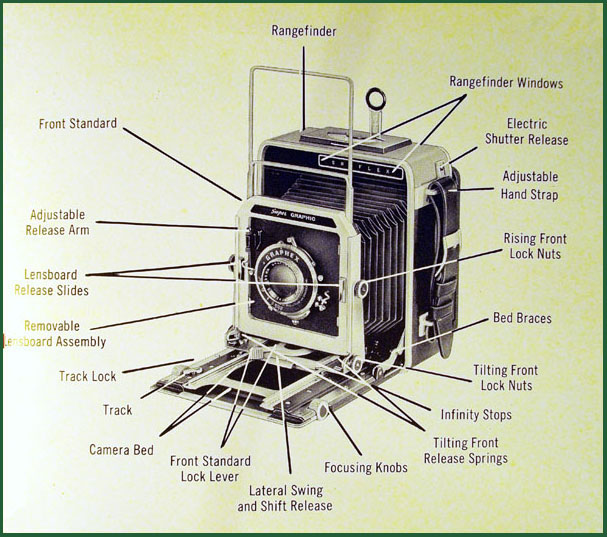

The front standard was much improved. Movements included the following:

- 15 degrees backwards tilt

- 12 degrees forward tilt

- 25 degrees swing from center

- ½” Shift from center

- 1 ½” rise

- 15 degree drop bed

The front standard controls image shape, distortion parallelism, depth of field, and composition. Adjustment knobs allow for locking in any position. There are built in front standard click stops to allow for easy return to the squared neutral position. A wire sports viewfinder frame was built into the top of the front standard. Two side mounted lens board release slides were pushed up or down to change lens boards. These release switches tend to get loose on cameras that have been used a lot. Rebuilding the front standard requires a number of special parts so it is better to obtain a camera where these slide locks are still tight if possible.

The last neat feature of the front standard was an internal solenoid which was built inside the lower standard. Boards were each made with internal adjustable trip fittings which allowed the solenoid to electrically trip the shutter using a side camera body release button. Every board also has a clip on the back. This clip was designed to hold and store the cam that matched each view lens. In well used cameras this internal trip solenoid is often burned out. Double extension bellows allow for full life size 1:1 macro photography. This bellows length allowed Graflex to make telephoto lenses up to 380mm. There were a total of 12 different common lenses that Graflex marketed for use with the Super Graphic Cameras.

Sync Plug

Sync Plug

The bodies were internally wired so each lens could be flash-synced through the camera body. Super Graphic cameras took a special 3 prong sync cord. There was a plug on the side of the camera body that took this special 3 pin coil cord. These cords came as a straight coil cord with a single PC fitting on the end. The straight cord plugged into any flash with a PC fitting. An addition Y cord could be used to fire the Graflex flash handles and the camera together using one button on the Graflex flash handle. Each lens board was wired inside

so every view lens could be flash synced through the camera body. The sync wires were located in the lower left and are visible in this rear board picture. A flash exposure calculator was built into the top of the camera. You set the flash guide number on a small metal wheel. When you focus the camera a red arrow points to the distance to your subject. Right above the footage reading the camera selects the f stop needed for a perfect flash exposure. This calculator worked great with manual flashes that had no automatic settings.

so every view lens could be flash synced through the camera body. The sync wires were located in the lower left and are visible in this rear board picture. A flash exposure calculator was built into the top of the camera. You set the flash guide number on a small metal wheel. When you focus the camera a red arrow points to the distance to your subject. Right above the footage reading the camera selects the f stop needed for a perfect flash exposure. This calculator worked great with manual flashes that had no automatic settings.

Most common focal length Super Graphic lenses are still available on the used market. Getting the correct Super Graphic board or cam is normally impossible. However pacemaker boards will fit a Super Graphic camera. When these are used only manual release of lenses is possible. Many of these 4-element Tessar type commercial style large format view lenses are no longer made by optical companies. However Yamasaki Optical Company, Ltd (established in 1924) still makes these lenses. Their lenses are supposed to be more compact in size and weight. Optics come with multi-coating and are sold under the Congo brand name.

The design this company uses is similar to the Kodak Commercial Ektar lenses. The lenses have good sharpness and contrast but like most Tessar formula optics they are a little soft towards the edge of the negatives. Numerous focal lengths from 90mm to 500mm are available. Many of their lenses have a very short flange to ground glass focusing distance. For instance their longer 400mm and 500mm lens may be used on the Super Graphic. These lenses are very reasonably priced; for a complete listing of all lenses go to their website. This company sells directly to the user. http://www.cosmonet.org/congo/index_e.html

As stated earlier, Sakai Tokushu Camera Company purchased the rights and original dies for the Super Graphic. Starting in June 1979 through 1985 they remanufactured the camera as the Toyo Super Graphic. The name on the front was changed from Graflex to Graphic. The top glass finder was dumped in favor of a center mounted shoe attached to the top of the camera. This shoe was used for a zoom optical finder. All screws were changed to metric. The flash sync terminals were changed to PC fittings. All other technical specifications of the body were exactly the same. The lens was changed to a 127mm f4.7 P-Toyonon lens in Copal 0 Shutter. Berkey Marketing Co sold this camera in the USA. You can still get many parts from Toyo. The price for a Toyo was $1,925.

© James S. Vilett, 10/2010.

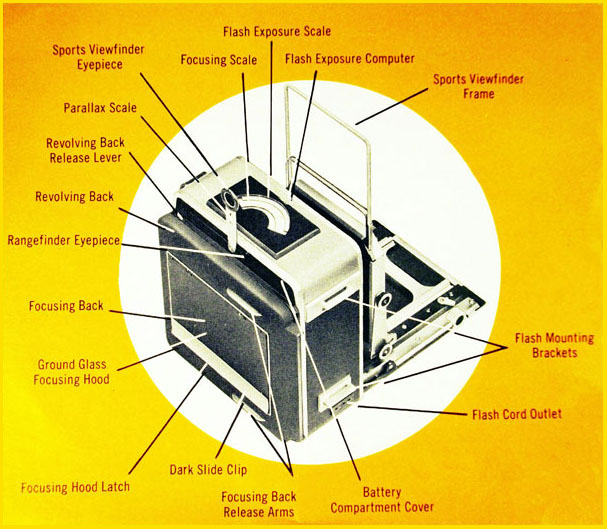

Super Graphic Parts Rear View

Super Graphic Parts Front View